Page 8 - Cerraduras Best

P. 8

5E SERIES

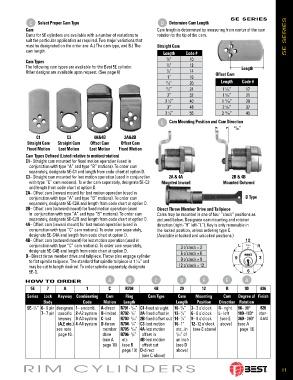

C Select Proper Cam Type Determine Cam Length

D

Cam Cam length is determined by measuring from center of the cam

Cams for 5E cylinders are available with a number of variations to rotation to the tip of the cam. 5E SERIES

suit the particular application as required. Two major variations that

must be designated on the order are: A.) The cam type, and B.) The Straight Cam

cam length. Length Code #

5 ⁄8” 10

Cam Types

The following cam types are available for the Best 5E cylinder. 3 ⁄4” 12 Length

Other designs are available upon request. (See page 8) 7 ⁄8” 14 Offset Cam

1” 16

11 ⁄4” 20 Length Code #

11 ⁄2” 24 1 ⁄16” 17

1

2” 32 1 ⁄16” 21

5

2 ⁄2” 40 1 ⁄16” 29

13

1

3” 48 2 ⁄16” 37

5

3 ⁄2” 56 2 ⁄16” 45

13

1

Cam Mounting Position and Cam Di rec tion

E

11 ⁄32”

C1 C3 4A&4B 2A&2B

Straight Cam Straight Cam Offset Cam Offset Cam

Fixed Motion Lost Motion Lost Motion Fixed Motion

Cam Types Defined (Listed relative to motion/rotation)

C1– Straight cam mounted for fixed motion operation (used in

conjunction with type “A” and type “B” motions). To order cam

separately, des ig nate 5E-C1 and length from code chart at option D.

C3– Straight cam mounted for lost motion operation (used in conjunction 2A & 4A 2B & 4B

with type “C” cam motions). To order cam separately, des ig nate 5E-C3 Mounted Inward Mounted Outward

and length from code chart at option D.

2A– Offset cam (inward mount) for lost motion operation (used in

conjunction with type “A” and type “B” motions). To order cam D Type

separately, designate 5E-C2A and length from code chart at option D.

2B– Offset cam (outward mount) for fixed motion operation (used Direct Throw Member Drive and Tailpiece

in conjunction with type “A” and type “B” motions). To order cam Cams may be mounted in one of four “clock” positions as

separately, designate 5E-C2B and length from code chart at option D. pictured below. Designate cam mounting and rotation

4A– Offset cam (inward mount) for lost motion operation (used in direction (right-“R” left-“L”). Key is only removable in

conjunction with type “C” cam motions). To order cam sep a rate ly, the locked position, unless ordering type C.

designate 5E-C4A and length from code chart at option D. (Available in locked and unlocked po si tions.)

4B– Offset cam (outward mount) for lost motion operation (used in

conjunction with type “C” cam motions). To order cam sep a rate ly, 3 o’clock = 3

designate 5E-C4B and length from code chart at option D. 6 o’clock = 6

D– Direct throw member drive and tailpiece. Throw pins engage cylinder

to flat spindle tailpiece. The standard flat spin dle tailpiece is 1 ⁄16” and 9 o’clock = 9

1

may be cut to length desired. To order spindle sep a rate ly, des ig nate 12 o’clock = 12

5E-D.

HOW TO ORDER A B C D E E A

5E 7 A 1 C R708 4B 20 12 R 90 626

Series Lock Keyway Combinating Cam Ring Cam Type Cam Mounting Cam Degree of Finish

Body Code Motion Length Length Position Direction Rotation

5E– /4” 6– 6 pin designate 1– uncomb. A-direct R701- /16” C1-fixed straight 10- /8” 3– 3 o’clock R– right 90– 90° 626

5

3

1

7– 7 pin specific 2-A2 system B-limited R702- /8” 2A-fixed offset in 12- /4” 6– 6 o’clock L– left 180–180° stan-

3

1

keyway 3-A3 system C-lost R703- /16” 2B-fixed offset out 14- /8” 9– 9 o’clock (see E 360– 360° dard

7

3

(A,E etc.) 4-A4 system D-throw R704- /4” C3-lost motion 16- 1” 12–12 o’clock above) (see A

1

see note member R705- /16” 4A-lost motion etc., in (see E above) page 10)

5

page 10. drive R706- /8” offset in 1 /16” of

3

(see A etc 4B-lost motion an inch

page 10) (see B offset out (see D

page 10) D-direct above)

(see C above)

RIM CYLINDERS 11