Page 3 - Herrajes Patricios - Best 9K

P. 3

Backset – 2 3/4” stan dard, 3 3/4” and 5” avail able.

Chassis – Critical latch and chassis components are brass or cor ro sion-treated steel. 2 1/16” di am e ter to fit 2 1/8” hole in door (Conforms

to ANSI A115.2). Lost Motion feature available as an option. (see page 5 for options/features).

Door thickness – Available for 1 3/4” to 2 1/4” doors only. Spacers available for 1 3/8” doors.

Roses – C – 3” Con vex, D – 3 1/2” Convex, K – 3” Convex-no ring, L – 3 1/2” Convex-no ring

Products protected by one or more of the following pat ents – 5,590,555 5,794,472 Other products patent pending.

Finishes –

(BHMA) US DESCRIPTION (BHMA) US DESCRIPTION (BHMA) US DESCRIPTION

605 3 bright brass 613 10B oxidized satin bronze, 622 19 flat black

606 4 satin brass oil rubbed 625 26 bright chromium plated

611 9 bright bronze 618 14 bright nickel plated 626 26D satin chromium plated

612 10 satin bronze 619 15 satin nickel plated 690 20 dark bronze

Antimicrobial Finish – 626AM satin chrome plated with UltraShield™ antimicrobial protected coating UltraShield ™

The BEST UltraShield™ finish inhibits the growth of bacteria and other microbes on the surface of the hardware.

NOTE: BEST's UltraShield™ option is recommended for use on any hardware application where product cleanliness is a high priority. i.e;. Hospital/Healthcare, Elderly

Care, Education, Transportation, Food-Service, Hospitality.

Latch – Solid brass 9/16” throw. Front 2 1/4” x 1 1/8” beveled.

Lever handles – Lever handles are a high-quality zinc alloy. Trim components are brass or bronze. Body is approximately 5/8” in

di am e ter; Handle is ap prox i mate ly 4 3/4” long (from center-line of chassis). #14 and #15 levers conform to Cal i for nia Administrative

Code Title 19 and Title 24. All three styles of levers conform to the Illinois Accessibility Standard.

Mounting – In addition to standard door preparation (ANSI A115.2 for 1 3/4” doors), two additional holes are needed for through-bolts.

Through-bolts require two 5/16” diameter holes located at 12 o’clock and 6 o’clock positions. A drill jig can be order ed to insure ac cu ra cy

of the holes. (see KD303 page 5).

Projection on door – Approx. 2 3/4” when mount ed on 1 3/4” door.

Strike – STK: Conforms to ANSI A115.2 (2 3/4” x 1 1/8” with curved lip & box). S3:

Conforms to ANSI A115.2 for 1 3/4” doors (4 7/8” x 1 1/4” with curved lip). S3-7/8:

Conforms to ANSI A115.2 for 1 /4” doors (4 7/8” x 1 7/8” flat)

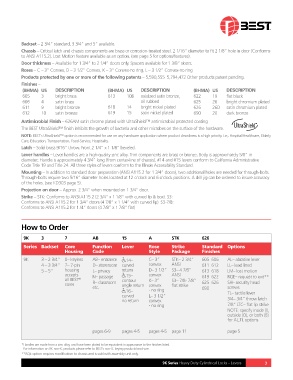

How to Order

9K 3 7 AB 15 A STK 626

Series Backset Core Function Lever Rose Strike Standard Options

Housing Code Style Package Finishes

9K 3 – 2 3/4” 0– keyless AB– entrance 14– C– 3” STK– 2 3/4” 605 606 AL– abrasive lever

4 – 3 3/4” 7– 7-pin D– storeroom curved convex ANSI 611 612 LL– lead lined

5 – 5” housing L– privacy return D– 3 1/2” S3– 4 7/8” 613 618 LM– lost motion

accepts N– passage 15– convex ANSI 619 622 RQE– request to exit**

all BEST contour K– 3” S3– 7/8- 7/8”

®

cores R– classroom angle return convex flat strike 625 626 SH– security head

etc. 690 screws

16– - no ring TL– tactile lever

curved L– 3 1/2”

no return convex 3/4– 3/4” throw latch

- no ring 7/8” LTC– flat lip strike

NOTE: specify inside (I),

outside (O), or both (B)

for AL,TL options

pages 6-9 pages 4-5 pages 4-5 page 11 page 5

* Handles are made from a zinc alloy, and have been plated to be equivalent in appearance to the finishes listed.

For information on 9K non-IC products please refer to BEST’s non-IC keying products brochure.

**RQE option requires modification to chassis and is sold with assembly unit only.

9K Series Heavy Duty Cylindrical Locks – Levers 3